Discussing the project with the team

Regina Laska before the refurbishment

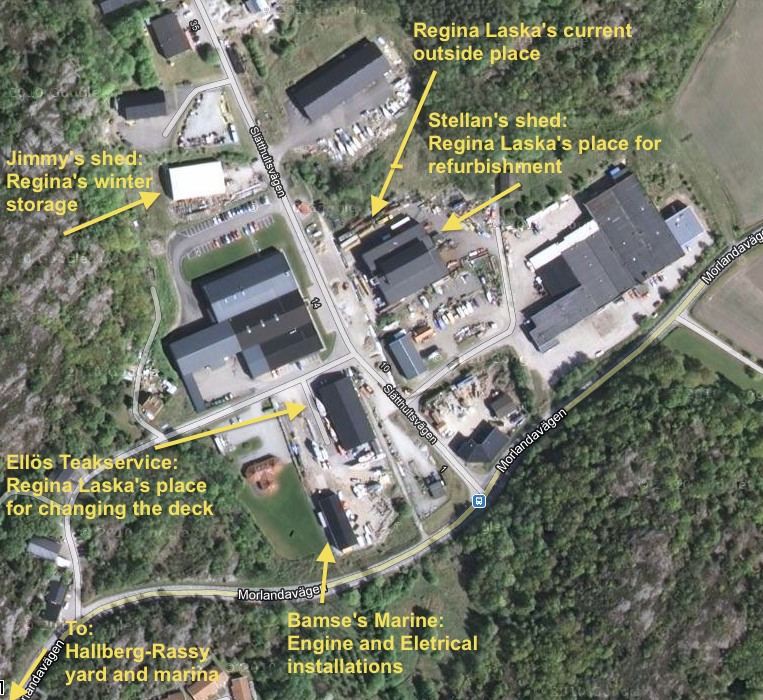

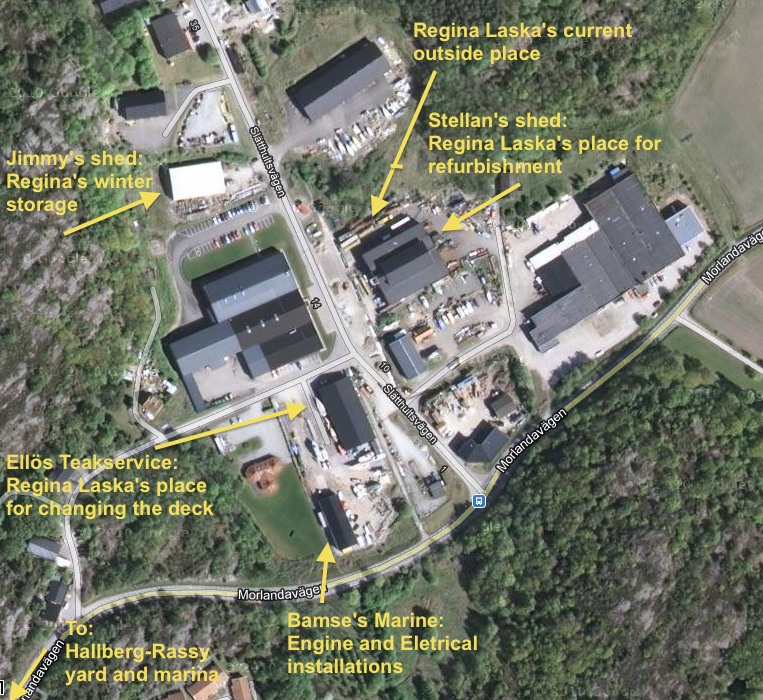

The industrial area of Ellös “Slätthult” less than a kilometre from the HR yard

Less than 1,000 metres from the Hallberg-Rassy yard, there is at least as much boat activity going on as at the yard itself. While the HR-yard solely concentrates on building new boats, there are a number of yards around Orust taking care of boats in the winter and/or refurbishing them. We are in the Mecca of boatbuilders!

Some of the better known yards for winter storage are Br Martinsson, Vindö Marine, Wallhamn Marina and Båtvårdsvarvet. Br Martinsson, by the way, was once the favorite yards for Sparkman & Stephens and many fine wooden boats have once been built by Br Martinsson. Wood is still the preferred building material for boatbuilders here on Orust, although hull and deck are since long made of GRP in today’s designs.

The entire island of Orust is liaised with boatbuilding in one way or the other and many people are or have been employed by one of the famous yards on Orust, such as Vindö, Forgus Yacht, Fantasi,Regina af Vindö, Malö, Najad, Nordwest, CR Yachts, Sweden Yachts and, of course, Hallberg-Rassy. During these times of economical downturn, some yards have been forced to reduce their workforce to reflect the current order stock, others have even gone bankrupt.

These times are, in other words, not only interesting in order to find pre-owned boats to very attractive prices, but the times are also very good to have them refurbished by the best imaginable boatbuilders. This is the main reason why we decided to truck Regina Laska all the way from Italy, where we bought her, to Orust in Sweden, where she was once built.

We decided against having Regina Laska refurbished at one of the major yards, and instead co-operate with the men and women who once have worked for Hallberg-Rassy and today have started their own businesses within boatcare. This team form a sort of virtual yard, all knowing each other and enjoying working together. The venue is the industrial area in Ellös called Slätthult, see picture above.

Carl, the spider in the net

Carl Adams, for instance, worked for Hallberg-Rassy for 22 years before he started his own business,Adams Boatcare. Carl is acting as the project manager for Regina Laska and has built a great team around our Regina Laska project.

This is where we found Regina Laska standing behind Stellan’s shed

The interest of the islanders was great when Regina Laska finally arrived in Ellös in May 2012. Two weeks later we arrived to Ellös as well by plane and the welcoming was overwhelming! No sooner had we found Regina Laska standing next to Stellan’s shed, and the first people started to show up. Carl had advised that we were on our way and the team wanted to meet us and see Laska.

Teak-Kai

First came Kai who runs Ellös Teakservice just across the road. He was already looking forward to having Regina Laska moved from Stellan’s to his own shed, where they will soon begin to rip off all the old teak and replace it with new. Standing on Laska’s deck he said that he found the boat quite sound and claimed it would all look totally different once she has a new teak.

Bamse

Soon thereafter Bamse showed up. Bamse’s real name is Göran Mogren, and he now runs Bamses Marin in Ellös and travels around the world to solve electrical and mechanical problems on boats. His eyes shone when he observed which boat we had acquired: “Oh! I know this boat! It’s hull No 99! I built her once and did all the electric and mechanical installation while I still worked for Hallberg-Rassy many years ago! I know this boat inside out and have also seen her in Italy when I was there working on other boats! If you need anything…. just call me! I’m across the road and would love to work on the project!”

Plastic-Pierre

Then came Pierre. He is a guru in plastic repairs and is used both by Hallberg-Rassy when they have to do some plastic repairs or he travels around the world to repair boats. With his professional eyes he examined the hull of Regina Laska while we became a bit nervous waiting for his judgement. Would she be good enough and pass? Or will we never get back the shiny appearance of the boat. Quietly, Pierre started to mix different pastes and liquids according to a secret formula an possibly there as a silent magic “Hokus Pokus”to be heard as well, before he started to polish a small test area on the blue ribbon. After a while he muffled: “You got an unpolished pearl there.” And then his judgement came out in a clear voice: “She has got potential. No damages to the hull. She only needs a good polish. It will take me about two weeks of work, but we will get there. At the transom I need to do some extra tricks, but you won’t notice.” He really liked the boat and despite him having loads of other jobs to do, he promised to have Regina Laska polished before the end of the summer.

The area Pierre used to do some test polishing. See the difference?

Anna-Wood

On the second day Anna passed by. Anna has worked for Hallberg-Rassy for many years and now runs her own business varnishing boats. She specializes in getting the wood on vintage boats looking like new. We saw her working on a beautiful classic Vindö 50 and she is doing miracles with wood getting it shiny like never before!

Anna working on a vintage Vindö 50 being completely refurbished

Carl Adams explaining the beautiful material of wood to Karolina looking at the old Vindö 50

When Anna went down below Regina Laska her face was glowing in excitement. She softly struck over the interior wood as if she immediately had fallen in love with Regina Laska. “Yes, it will be quite some work to get her into the same shape as your HR40, but I can do it, no problem. The interior wood is not damaged, so that’s good. She just needs many hours of love and treat!” Anna looked as if she wanted to start working right away.

The interior of Regina Laska showing many places where work needs to be done

The inside of drawers and cupboards need at least as much attention as the outside surfaces

The companionway where water had found its way inside the boat

This all doesn’t sound too bad, I felt. All these professionals seem so positive about Regina Laska! Deck, hull and interior under control, I thought, and pictured that we had come a huge step forward in the project. We began to to see a great team forming.

Pelle Sundbye, the fireman, onboard Regina Laska

Fire-Pelle

A person we didn’t know before was Pelle Sundbye, who originally came to see our HR40 Regina.

As it turned out, Pelle was a fireman and got so interested in our project that he immediately agreed to become our “fire fighting consultant” and began to work out a fire safety concept for Regina Laska.

One week later, he came a second time, to take measurements onboard and to plan the installation of fire alarms, fire blankets and various types of fire extinguishers placed in strategic places.

The goal is to fight a possible fire without unnecessarily damaging the boat, Pelle said and then explained how to best use CO2, foam and powder to extinguish a fire. Often the entire engine, all electronics or the whole interior get totally destroyed by using an inadequate fire extinguisher, when there possibly was only a very little fire that could have been put out easily by using another type of extinguisher. “You don’t need to shoot flies with canons and blow up the whole house!”

Pelle discussing where to best place a 10 kg CO2-extinguisher for the engine room. Karolina is taking measurements in the cockpit locker.

Whisper-Martin

The following day we had a meeting with Martin Lindgren, with whom we had worked before when it comes to power solutions onboard. Having been employed by Mastervolt for many years, Martin has now started his own business called Sellpower AB in Sweden, representing WhisperPower, amongst others. Martin walked along in the boat, took measurements, looked quite concerned at times and then again he nodded his head and started to visualize what was to be done. “This will be great for our new products!” he proclaimed. “Whisperpower is coming out with some really hot stuff, you see! My aim is to minimize necessary cables, to maximize easy to reach storage space, to get ample power, to have full control, as well as to have a safe, relative simple, robust and comfortable boat with a lot of redundant charging and battery facilities!”

Martin Lindgren trying to find the best power solution for Regina Laska

So many ideas! Martin promised to get back within shortly with a drawing of the entire power system.

The owner has installed small DC-DC converters and DC-AC inverters at various places in the boat. The new electrical concept will be simple, robust, redundant and easy to understand

Henrik, the rigger

One very important member of the team is the rigger Henrik Jakobsson from Wallhamn Marina. He drove from the neighbouring island Tjörn and climbed high up in Stellan’s shed in order to reach the mast, which was stowed just under the ceiling. Henrik is used to climb masts, so climbing along a wall does not seem much different.

Henrik Jakobsson hanging over Laska’s mast to examine how much needs to be done

While hanging over the mast, he was examining the same, while I was nervously waiting for his judgement from underneath. After all, the rig is one of the most expensive parts of a boat and its refurbishment would mean a major investment from our side. It all depended on the condition of the mast. Minutes felt like hours. I could just hear some humming from far above our heads. What has he found?

Henrik measuring the gap for the furling mainsail to be sent to Elvstrøm Sails in order to optimise the sails

As the other members of the team, also Henrik commented on the sturdiness of the equipment of a Hallberg-Rassy. Yes, the mast was sound and strong, and just needed a lot of love and care. All halyards need to be replaced, just as the wires for the stays and shrouds. A new profile for the furling head stay, but otherwise the winches, turnbuckles and the mast itself seemed to be in a good condition. What a relief!

We agreed on replacing the manual furling systems to electrical ones. The mast will get a built-in motor so we can furl the main sail in and out from the cockpit without having to go on deck. This will be very convenient, since we have as a rule that nobody must leave the safety of the cockpit without someone else watching. At the same time, we will replace the head furling system to an electrical one. So, also the head sail will be furled by means of pressing a button.

Henrik will also install all antennas in the mast, the foghorn, the navlights and the radar, build new cable canals and pull the corresponding cables through the mast. He will use his special tricks to clean the mast and grease it with paraffin wax. In spring, he will polish and wax it. He promised the mast would shine as new when Regina Laska will be launched the following spring.

Carl Adams offered to drive the mast to Wallhamn Marina with Stellan’s very long special mast trailer, so Henrik would be able to do all the work in his workshop.

The team is really working well together!

Henrik, the rigger, examining the turnbuckles with all stuff we have taken out of Regina Laska in the background

Going through the boat with Carl

Carl and us went then through the boat investigating what more needed to be changed. You bet there was!

The previous owners seemed to have used the pantry top as a chopping board and we discussed to replace it. This would be a major and expensive job, especially since we were talking about Corian as the material in question.

Carl Adams examining the hard-top. Yes, the ceiling has to be changed

In order to get the washing machine into place, a wall has to be taken down in the forward head, which Carl said he would replace by a plexiglass door for the shower compartment, getting rid of the shower curtain. The cupboard, where the washing machine is to be installed, has to be taken down and re-built in order to become larger to find space for the washing machine in question. One issue to consider is that the door of the washing machine has to open the same way as the cupboard door. A lot to think about!

The cupboard for the washing machine. Never mind the stains, the entire cupboard will have to go anyway….

Regina Laska is lacking holding tanks for the blackwater from the toilets. So, here again, more walls are to be taken down and doors are to be fitted and things need to be moved around in the engine room to give space for the holding tanks.

The ceiling of the hard-top needs replacing and also parts of the ceiling in the boat itself. Luckily, Carl has been working as a carpenter, amongst others, and has no fear from taking down bulkheads and putting up new walls. “It’s only wood!” he proclaimed! In deed, for these men and women wood is like clay that you can form any way you want.

All through-hulls have to be replaced and, while doing so, we’ll change the type at the same time, so they will work when eventually changing to water cooled fridge and freezer

Since we wish to have a lightning protection in the boat, similar to what we have on our HR40 Regina, one of the water tanks has to be taken out in order to get access to the keel bolt. This is a major job, but since so much is leaving the boat anyway, e.g. the saloon table and the floor boards, in order to be re-varnished by Anna, we can just as well take out the tank, Carl thought. Then, the mast on the coach roof has to be electrically connected to a cable leading along the mast step down to the keel bolt via a one millimeter gap to avoid galvanic corrosion. All clear? A lot to think about…

The lamps have corroded in the salty environment

All lamps are to be replaced since they were corroded and the golden colour is not to our taste. Fortunately we have Mattias of Båtsystem as part of our team. He came onboard Regina Laska in order to check the potential. After some investigations and thinking, Mattias came up with some extraordinary ideas on how to create a feeling of space and coziness by means of light. We both felt this to become a very successful project and during the next few months we agreed on meeting frequently in order to work out a light concept for work, night-sailing, relaxing, entertaining and reading.

Mattias from Båtsystem tries to find the right angles for the LED light-slings together with Carl

All water taps and showers will be replaced by more modern ones of highest quality. The upholstery will be changed and so will most windows and all hatches due to the UV light having destroyed themin the Mediterranean sunlight.

New battery boxes have to be built to fit under the floorboards where the domestic 580 Ah/24V GEL-batteries (corresponding to 1160 Ah at 12V!) are to be fitted and the old battery boxes under the aft cabin berth are to be taken out in order to give more storage space. This is also where the two 40 inch membranes for the new 230V watermaker will be placed, but where will we place the 230V high-pressure pump for the Echotech Watermaker? And will there be room for the new 7.5 kW Westerbeke diesel generator? Our brains started to turn faster and faster and during some days we just felt that the confusion increased. Was this project still under control?

“No worries!” was the standard expression by Carl Adams, who had a solution for everything and always seems to know exactly the right people for the various jobs.

The cupboard buttons have once been golden.

I can’t see how this heater outlet ever has been considered being elegant

Since the upholstery in the V-cabin was ripped already, we opened up more to see if the foam inside could still be used

One of the windows which have suffered in the continuous UV-light

The hatches are being replaced as well

“The good thing is“, Carl continued, “that we take off everything from the deck anyway, since we are replacing the teak. So when we have taken off the windless, for instance, I can take it to my workshop to find out why it leaks oil.” It seems to be a never ending story!

The windless is leaking oil. I hope it doesn’t have to be replaced as well!

While we went through the boat with Carl, we made notes. And every night we sent a new long e-mail to Mellie Rassy at Hallberg-Rassy Parts AB to increase the order even more. Mellie is then calling the suppliers and negotiates the prices. Or she has the possibility to just go to the HR yard and get the requested item from their stock so we get the newest fittings being used for today’s HR boats. This way, we may take advantage of the good prices the procurement department of Hallberg-Rassy is getting when buying stuff for their own production. Also, I don’t have to pay for any shipping costs since it is being delivered together with other equipment to the Hallberg-Rassy yard anyway. It is very convenient to shop at Hallberg-Rassy Parts AB!

Leon measuring one of the cutter stay sails with Regina Laska in the background. We found one extra spare mainsail, one extra spare genoa, one light wind genoa, one gennaker and no less than three cutter stay sails onboard. The storage space on a HR46 seems huge!

During one week, Karolina and I were working with emptying the boat from all the stuff that the boat came with, ranging from spirits to rusty spanners. There seems to be a lot of space in a HR46 and it was much more work to go through every little spare-part to find treasures before we dared to through it away or giving it to someone who wanted it.

It took an entire week for us two to empty the boat and go through all that came with it

Treasure, spare-part or scrap….?

Always good to have a spare spanner!?

I felt satisfied and happy with our decision to take the extra cost and to have Regina Laska trucked all the way from Italy in order to get her refurbished here on Orust. This is where she belongs and here we can find exactly the right people who are so positive and supportive. These men and women know these boats inside out, have done similar jobs many times before and work so well together. The communication, be it across the street or with the Hallberg-Rassy yard it fantastic.

Germán Frers sailing a Hallberg-Rassy

(photo courtesy of Hallberg-Rassy)

But not only the people around Ellös are fantastic! Also people from a bit further afield were working enthusiastically with the project. Steve Moffatt, who is working from the UK on getting Regina Laska through the commercial coding, has been in contact with a Naval Architect called Stuart Roy in England, who will help us providing a Stability Booklet which is needed if you wish to sail offshore commercially (MGN 280). The problem was just that in order to work out the Stability Booklet we need the plans for the HR46 to avoid having to employ two people for two days who would take the lines off the vessel itself. I sent off an e-mail to the designer of the HR46, Mr Germán Frers in Argentina, who immediately replied that he would do what he could to help us with this project. I was overwhelmed!

I have been a huge admirer of Germán Frers for decades. Germán was working for Sparkman & Stephens as one of the team’s principal architects in the 1960’s and I suppose it was from here he got the taste for beautiful lines and innovations. Germán’s eye for appealing designs can be followed through all of his 600+ designs, ranging from Whitbread boats, Maxi’s, America’s Cup boats and elegant cruising boats, such as the Hallberg-Rassy.

Germán Frers at the Hallberg-Rassy stand at Boot Düsseldorf 2011 (photo courtesy of Hallberg-Rassy)

With such a great team and so much support, we are now convinced this project will become a very successful one. We are eagerly looking forward to working with this wonderful team of professionals!