Refit year 6

Regina Laska joining up with many other Hallberg-Rassy boats at Adams Boat Care, Sept 2017

Improvements for 2018

On 23 September, I left Regina Laska in the good capable hands of Adams Boat Care together with a list comprising no less than 120 points of refit work. This will be her 6th year of refit in the never-ending process of updating, refurbishing and improving an already fantastic boat. At the same time, this is also the 10th anniversary with Adams Boat Care, since, before Regina Laska, I used to keep my HR40 Regina with Carl Adams as well.

10 years of experience with the best people I know to take care of our beautiful Hallberg-Rassy boats!

In the beginning I was one of maybe 2-3 boats that Carl took care of in his free time, while still being employed by Hallberg-Rassy. Today, I never stop becoming impressed by the annual growth of what has now become Adams Boat Care AB on Vindön, Orust. Each time I return, new employees keep greeting me at upon my arrival, as well as a large number of HR’s of all sizes coming from all over Europe. Many of the new team members I know from other yards and companies around Orust and I must say that Carl and Anna are really successful in gathering the best people around them. I believe it’s the joy of working there that makes all the difference?

HR49 Stella Maris (left) came sailing all the way from Turkey in order to get a well-deserved total refit for world-wide cruising. Regina Laska in the middle background together with many more HR’s waiting to be lifted and refitted by Adams Boat Care AB.

The most impressive and surprising view was, however, to see a 50m motoryacht berthed next to all the HR’s. This is one of two superyachts who now call Vindön their home port. The other superyacht is a sailing yacht where the mast is to too tall to fit under the high-voltage cables that block the entrance to the archipelago at a hight I was never thinking of every could block out a boat…. It has to be demasted before motoring into the archipelago and will then come for its refit in due course.

While sharing premises with Adams Boat Care, these superyachts have their own crews working on the boats. Carl welcomes that these superyachts now form part of the marina and is looking forward to a widening scope of boat owners and boat builders that comes with that.

One of two superyachts who will share marina with Adams Boat Care and have Vindön as their homeport for their annual refit. Apparently, Regina Laska is in good company… :-)

New engine

I thought I’d post some of the work done on Regina Laska.

First of all, Regina Laska will receive a new main engine. My reliable and good old Volvo Penta TMD31 will be retired after 20 highly appreciated years onboard Regina Laska. My old Volvo Penta will now spend remaining years as pensioner in a Swedish double-ender driving up and down the Götakanal. I am sure my engine will enjoy the calm canal and give many years of pleasure to the new owner.

My good friend, the Volvo Penta TMD31 (green) will be retired in 2018

The new engine to be installed in Regina Laska will be the Volvo Penta D2-75 with less vibration, less noise, better fuel economy and all the reliability that comes with a brand new engine. Adams Boat Care has already installed this very engine in two other HR 46’s with very happy customers praising the D2-75 as as “smart little strong engine” (quote from John Neal on Mahina Tiare III, who was refitted by Adams Boat Care two years ago).

For me, it was very important that this is no engine with common rail (I don’t want a lot of electronics on a marine engine!) and that it in the base is a marine Perkins engine and not a converted car-engine.

A new Volvo Penta D2-75 in HR46 Mahina Tiare III. Notice the huge space that opens up with this smart little engine.

By changing engine, I will save 136 kg in weight.

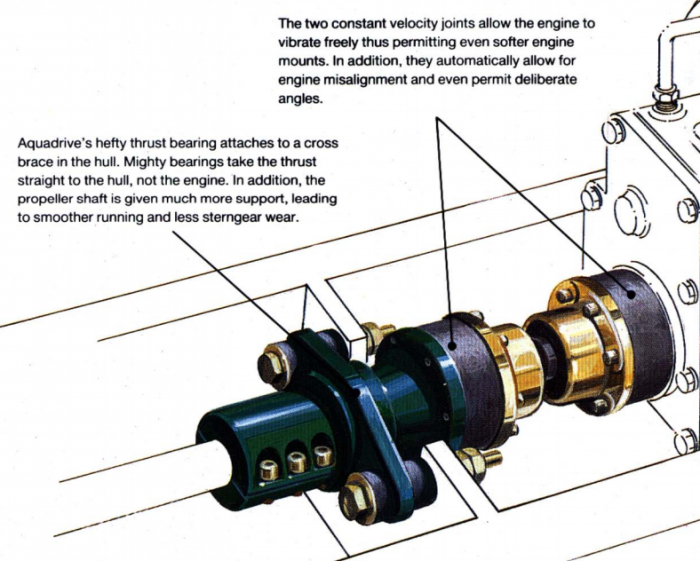

Aquadrive antivibration system

Between the gearbox and shaft, an Aquadrive flexible couple will be installed in a new bulkhead in the engine room.The propeller shaft is aligned to an Aquadrive thrust bearing, which absorbs the propeller thrust. This way, the propeller does not push the engine, where the force continues through the engine feet. Instead, the propeller pushes the new bulkhead. The flexible coupling leads to yet less vibration and an engine, that does not have to take any axial forces.

Another HR46 where Adams Boat Care have installed a D2-75 for a very satisfied owner. Note the Aquadrive with its dedicated bulkhead just aft of the gearbox und under the white exhaust silencer (bottom right).

To decrease the engine noise under deck even further, the main engine doors will be tightened and the cupboard to the watermaker controls and 230V system will also be tightened in order to prevent noise and smell penetrating from the engine room to the interior of the boat.

New propeller

If you have sailed on Regina Laska before, it might be nice to know that I have ordered the engine with the same prop-walk as before, so you do not have to change your habit to turn to port in a tight space or berth starboard-to.

A new propeller becomes necessary due to the change, but I will stay with the successful Flexofold, which has proven to be highly efficient with little slip and low vibrations.

New alternator

While I’m at it, I will have a new 24V/110A alternator installed.

New water heater

In the engine room, a new hot-water boiler will be installed with twice the power compared to the old one. Thanks to a powerful 2 kW heating element, the water will be heated three times as fast as standard and twice as fast as Regina Laska’s old water heater. The insulation of the water heater is also improved, just as the stainless steel outer and inner shell will be ore corrosion resistant and look smart.

Another important feature of the new hot water boiler is that the hot water in the taps will not be as hot as before, avoiding possible burns and allow for safer showering.

New batteries

The 5 year old eight 145 Ah AGM Batteries for the 24V system will be replaced by four 160 Ah Li-Ion batteries by Whisperpower. Each battery has its own computer, communicating with the other batteries for optimal and safe charging.

These are Litium-Ferrite batteris and thus have a significantly higher safety standard than ordinary LiIon batteries wich are, for instance, found in electric cars. By changing battery type, the capacity will be more than doubled compared to today (thanks to the fact that LiIon batteries may be emptied to 10%) and the lifetime will be become 12 times as long (5,000 cycles instead of 400 cycles for AGM). LiIon batteries also have the great advantage that they can be charged much faster with higher amps all the way up to 100%, reducing the hours running the main engine or the generator.

Before (with 8 x 145Ah/12V AGM) at 24V:

Total capacity: 580 Ah

Theoretically max usable: 290 Ah (discharge to 50% and recharge to 100%)

Practically usable without shorepower: 175 Ah (discharge to 50% and recharged to 80%)

After (with 4 x 160Ah/12V LiFe) at 24V:

Total capacity: 320Ah

Usable: 290 Ah (90% discharge)

In other words, the total usable power remains the same in theory and increases by over 50% in practice, while recharging is done during considerably less time, saving hours on the engine/generator. The saving in weight is 185 kg. Self-Discharging is considerably less, and does not harm to the batteries. Any state of charging is acceptable over time so they do not have to be re-charged immediately to avoid sulfatation as with AGM/GEL/Lead-Acid.

Considering the longer life span of LiFe, the total cost is also decreasing, making this investment a very sensible one when looking from all aspects (power, recharging time, self-discharging, weight and total life span cost).

The starter battery for the generator and the main engine will also be replaced by an identical 100Ah AGM battery.

The 12V emergency battery for basic navigation, communication and lighting has already been replace last year.

The new batteries and the new engine together will save a total of 376 kg (!), which should be transformed into better and more comfortable sailing performance.

Fixed furling cutter stay

Talking about sailing performance, the rig will be changed from sloop to cutter. This means that a fixed cutter stay with a furling cutter stay sail will be installed. Both the furling and the necessary checkstays will be controllable from the cockpit. The spectra checkstays will be replaced and upgraded from 6 to 8mm. This means that sailing upwind in gale-force wind will become much more comfortable.

Testing the cutter stay sail on a removable cutter stay during summer 2017. Note how beautifully the sail is sheeted in and how flat it is! It’s thus a great upwind sail in heavy weather!

During the sailing season of 2017, I have tested my loose cutter stay sail. Sailing upwind in winds of 30+ knots is a joy with Regina Laska riding over the waves. The centre of sail area is centered around the mast with the headsail further aft and the furling main further forward. Since the cutter stay sail (in Hydranet cloth) is much smaller than the genoa, it does not have to be furled up in higher winds and stands flat like a beautiful shield, decreasing heeling and improving speed against the wind.

Testing a new type of Nano technology gelcoat sealer

A new nano-technology by Nanogate implemented in a gelcoat sealer by Feldten Marine will be tested to fill up and smoothen the gelcoat to give an extra even surface on the hull, where no dirt is said to find a possibility to stick.

We will see if it works. I’m a bit sceptical, but, at the same time, I’m a bit interested in how new chemicals perform….

Lower steering board to stand on and new teak on cockpit floor

To follow guests’ request, the standing board for shorter people standing at the steering wheel will be lowered by 10cm for a better view over the hardop and better reaching the steering wheel.

Taller guests will stand on new teak, by the way, since the cockpit floor will receive new beautiful teak.

USB-charger in reading lights

Down below, all reading lights in the guest cabins will be replaced by a new type of light with built in USB-socket. This means you do no longer need to bring a 230V phone charger, but can plug in your USB charging cable for your phones directly into the reading lamp over your berth.

New companionway ladder

Regina Laska will receive a new stylish companionway ladder with swung footsteps to facilitate climbing down into the salon or up into the cockpit while heeling.

Smart rubber in several grooves will act as antislip for safety and style. Integrated steplights will not only look smart but allow for safer use of the stairs during nights.

The new companionway ladder being glued together by means of numerous very thin pieces of teak. Built-in LED lighting by Båtsystem will lit up the steps during night.

Old companionway ladder (left) and new, still to be varnished (right)

Other small upgrades

Guest using the port forepeak berth will receive an own little shelf under the cupboard to place phones, their water bottle and other small items.

The forward toilet will receive a new seat for comfort and hygiene.

Last, but not least a number of smaller repairs, maintenance and service fill up the list to its 120 points for refit work done during the winter of 2017-18. Among these are, as in every year, the annual inspection and service of the fire fighting equipment, all life wests, the life-raft, the medical supply, the Propane gas system etc.

Welcome onboard!

Visit to Adams Boat Care in February 2018

As in every year, I go and visit Adams Boat Care to discuss the progress of the many refit-points (and add one or two extra on the list…). It’s a bit shocking to see how much work there is actually put into the boat each year! She was stripped down once again and the boatbuilders were busy installing all new equipment.

The old engine has been taken out and the new Volvo-Penta D2-75 was already standing on the side dock waiting to be lifted on onboard. It had already its new second High Output Alternator in place, controlled by a new external regulator, which is optimised for Litium batteries.

The Li-Fe batteries had also already been installed under the floorboard, together with the control box and programmed for the boat.

The engine room looked empty after the old engine had been taken out. Good space to rebuild other items in the engine room as well, while we’re at it…

With the engine taken out, the stern tube seal is easily accessible, so Regina Laska gets a new “Black Jack”, replacing the one installed five years ago during refit year 1.

While we’re at it, why don’t we…. change all the water hoses?! And the water heater with it? All domestic water hoses will thus be changed to new ones to give best possible water taste and also since old hoses might get brittle more easily. The water heater will be a stainless steel one from Isotherm with double heat exchange pipings and an upgraded 2kW water heater element. The double pipings allow for both engines to heat the water. In other words: If I run the main engine, the Volvo’s cooling water will heat the water, and if I run the generator, the Westerbeke’s cooling water will heat the water as well. This will reduce running the generator for longer than necessary. The generator will thus heat the water by means of excess heat from the cooling system as well as thanks to the upgraded 2 kW heating element. Will also gives a further redundancy for heating water. Water heating will be as quick as charging the Li-Fe batteries now!

Talking about heating, a third heater will also be installed this winter. Further to the two Webasto diesel heaters, Regina Laska will receive a third heater by Ebersprecher running off the excess heat from the Volvo Penta’s cooling water. Similar to the water heater, the Volvo’s cooling water with hus first go through the water heater and thereafter through a heat exchanger that heats air that is blown into the boat.

The Ebersprecher heat exchanger: Engine cooling water is led into the heater. Cold air is then taken from the cockpit locker and blown into the aft bathroom and under the main companionway stairs.

The new control for the third heater (top right)

While motoring, we can thus heat the boat by means of the Ebersprecher cooling-water heater. It will have two outlets: One just under the companionway that heats up the cockpit under the hardtop and one outlet into the aft shower compartment. Motoring long, cold rainy days, we can thus dry clothes in the aft shower while, at the same time, enjoy a warm, comfortable atmosphere under the hardtop without having to run any of the Webasto Diesel heaters. Last, but not least, three heaters give one more system in redundancy.

All hoses for both engine’s cooling water systems will have valves in order to bypass the water heater, should it break.

There will be a special emphasis on sound shielding with the new Volvo Penta D2-75. First of all, the engine should run as vibration-free as possible. Therefore, a new Auqadrive is being installed.

The Aquadrive means that the propeller thrust is passed into the hull by means of a dedicated bulkhead rather than via the motor itself and it’s rubber feet. Therefore, a new bulkhead needed to be moulded into the engine room of Regina Laska, where the thrust will be taken up.

Looking down from the cockpit floor. You can see the new bulkhead moulded into the hull by the shaft (greenish colour). This is where the propeller forces will be taken up by the Aquadrive.

The Aquadrive will make a huge difference to avoiding vibrations to pass into the boat, giving a smooth snorring sound of the engine.

But also the snorring sound of the engine is to be kept inside the engine room and shall not enter the cabin area. Two leaking of engine noise have been identified. a) through the engine room doors and b) through a cupboard door above the engine room, where the watermaker control panel and the 230V centre is placed.

The engine room door locks have therefore been re-designed to make sure the door closes really tight. The louvre cupboard door above the engine room has received a plexiglass covering the louvres as well as a special sound seal around the edges to prevent motor sound to enter the cabin.

All the instruments have been taken out of the pedestal, so that it could be lifted off more easily. New engine instruments are to be built into the pedestal and the teak deck is to be replaced on the cockpit floor (this was never done before, but since the pedestal had been lifted off, we could just as well change the teak deck on the cockpit floor, I thought).

I must admit, it all looks quite awkward and one wonders if this ever will turn into a fine yacht again… It’s the sixth time I do this on Regina Laska, each time refitting even more items. Every year I say: Now she definitely must be ready, but then I find new ideas what one could improve even more. My experience is luckily: Yes, she will be looking perfectly again by the time I return in spring!

Let’s now look at some things that have been dealt with already:

The forward anchor locker has been emptied and all the bolts holding the fitting for the forestay have been replaced. The entire compartment has been painted from the insida to look good.

The clean and freshly painted anchor locker with the bolts holding the forestay renewed.

The gas locker has undergone the same face-lift. The problem is that iron Camping Gaz bottles stand in some water and rust heavily. Therefore, Carl will build a little shelf so that the gas bottles do not stand directly on the floor and in the water.

The cleaned and freshly painted gas locker.

The new teak ribbons to lift the iron Camping Caz bottles by 45mm from the bottom, preventing from from rusting, standing in the water (right). To the left the stainless fixing for the (much superior) 6 kg aluminium Swedish gas bottle (that don’t rust – thank goodness!). I have both systems since you cannot fill the Aluminium bottles within the EU. For the EU I use two Camping Gaz bottles on top of each other.

Regina Laska has received a new Flexofold propeller, despite the fact that the old one was no older than 3 years old. The reason is that for the new motor, we needed a RH prop. Since the new Volvo Penta will kick to port in reverse (RH propeller), we will berth with the port side to the quay preferably. On this side, there is the diesel filling cap! To help to avoid mixing up water and diesel, Carl has marked the caps on deck clearly with text and colour.

The reason why the teak around the water cap looks a bit lighter is because Carl has detached the water filling pipe from the deck in order to seal it off properly. When sailing hard with the foot-rail under the water, some drops of water were leaking into the boat.

All winches have been serviced and put together with Tefgel placed wherever there are two types of metal touching, e.g. where stainless steel screws are screwed into brass. The winches were in excellent condition, also thanks to the fact that they are being used regularly and serviced annually.

The step where shorter sailors can stand on in order to look over the hardtop while helming has been lowered by 10 cm as per guests’ request. This way, you are standing comfortably and can still look over the hardtop, but can access the gear level comfortably.

Down below, the ceiling has been taken down in order to get access to all bolts holding the genoa sheet traveller. All nuts were tightened, since they had gone loose after many thousands of miles sailing. Now they are all tight again and no squeaking noise should be heard any more when sailing in tough weather.

All mahogny curtain lists have ben replaced in order to give an upgraded and elegant feel in the salon.

A new shelf has been built for guests in the forepeak, sleeping on the port side. This berth had previously lacked somewhere to place the telephone, the watch etc. The shelf is built right under the reading lamp, which will be replace for 2018. All reading lights in the cabins will now feature a built in USB-charger so that you can charge your phone directly from the reading light.

The hob and oven has received some lead weights on one side, so that the oven is perfectly balanced. Before, when I was frying eggs, the eggs were sliding to one side of the saucepan, which I found annoying. When frying, I like when the saucepan is remaining perfectly horizontal, even when the boat is rolling in the seas.

New steplights will be installed on the stern platform so that the steps down to the swimming platform will be lit up for easier boarding from astern in the dark.

All rails for the hanging lockers have been lifted somewhat to allow for more space for hanging cloths underneath.

The guests’ toilet has received a new seat. After 5 years I felt it was time for a new seat, so the boat always has a fresh feel to it.

The holder for the toilet brush has been fixed so that it cannot move in heavy seas.

Under the aft cabin berths, bulkheads have been installed so that spare parts and other items can be stowed thereunder without interfering with the steering system.

The top bunk in the side cabin has been rebuilt to get rid of the squeaky sound that could be heard when a guest was turning around in the berth. This way, the person sleeping underneath should not get disturbed any more.

The new companionway ladder was in place, but still covered up in paper, not to be scratched. Carl and Anna are checking the placements for the LED lighting of the stairs.

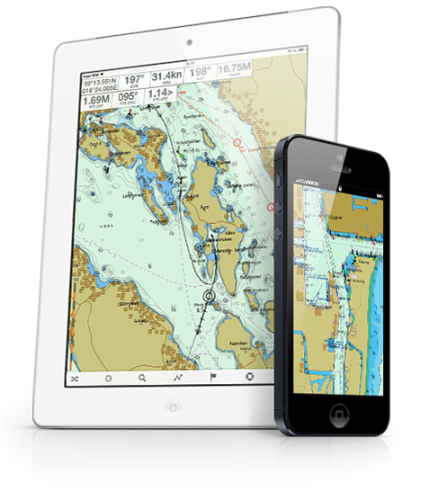

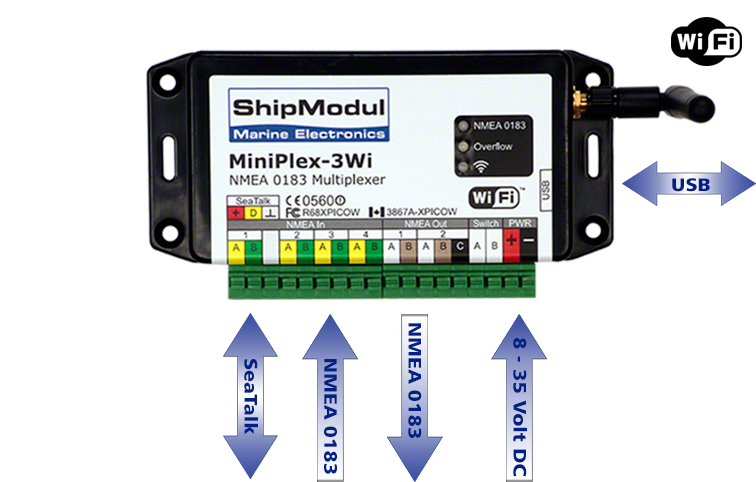

On the navigation side, a new navigation system is being used as an independent third backup to paper charts. The new navigation system is a professional system normally used by pilots when they come onboard a big vessel to guide them through difficult passages.

When today’s pilots board a ship, they often use SeaPilot running on a standard iPad. They hook up the SeaPilot to the onboard system and have thus access to the ship’s data as well as their individual own charting system. The charts are official S-57 ENC’s (official Electronic Charting systems) which are updated more regularly than other electronic charts. They also come directly from the source (Hydrographic Offices) and thus lack any errors or delays due to the process and look exactly like the professional charts used on ships.

The SeaPilot system will be introduced to student and guests from 2018 onwards. Each guest is welcome to bring their own iPad and download the navigation App for free. The official S-57 charts for the area in question can be obtained as well during the cruise, so each of you can check the navigation on your own individual professional navigation system. Just as with professional pilots, your iPad is being hooked up into the ship’s data network, so you can receive live AIS data as well as the ship’s position, heading, COG and SOG. This data will be transmitted via WiFi through a new Multiplexer onboard.

Feel like your own pilot!

The team of Adams Boat Care AB are checking the entire boat in every detail. Sometimes they find things that I haven’t found, like when Carl e-mailed me about corrosion in the hardtop windows. Of course, the same applies for windows in HR soft-tops.

He will clean and grease everything for this coming season, but it seems as if Carl has already put the first item on the refit list for next winter, which is to become the seventh refit year of Regina Laska. We are talking about new stainless steel frames for the hardtop windows, which are more robust and sturdy against the salty harsh marine environment compared to aluminium. And besides, it looks shiny and cool as well. I have seen Adams Boat Care’s own hardtop design, and it does look look with stainless steel frames, doesn’t it?!

Years of exposure to the salty marine environment with green water on deck splashing against the hardtop is wearing hard on the aluminium window frames. Time for new windows with stainless steel frames next year?

Example of hardtop with stainless steel windows as produced by Adams Boat Care.

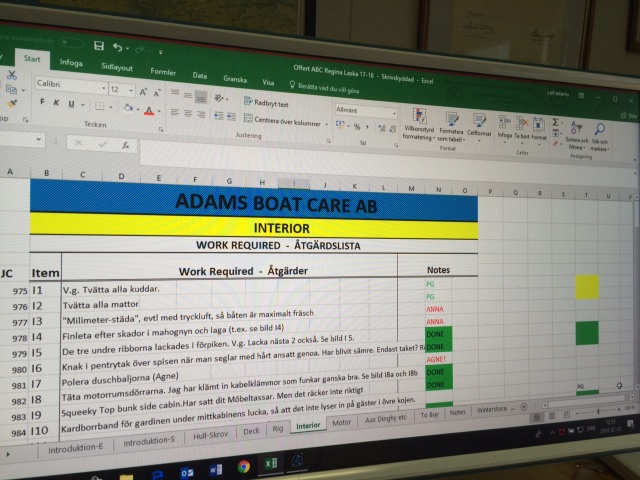

There are, of course, many, many more points on the list – far too many to mention. We sat hours in the conference room discussion each and every point, of which just a fraction were mentioned here or can be shown on the below spreadsheet.

Thank you all at Adams Boat Care for yet another fantastic refit year! My guests will appreciate your fantastic work!

Next time I came, I am sure the sails and the rigging has been looked after as well, including the installation of a fixed cutter stay sail, new running backstays and spraying the main sail with McLube by Harken in order to make it furl in and out more smoothly.

Regina Laska has been launched!

While still on my RYA Yachtmaster Theory course in Malta I have just received the piece of information that Regina Laska has been launched. See below photo.

I look forward to seeing her myself next week after her extended sixth refit in six years. More information to follow in due course!